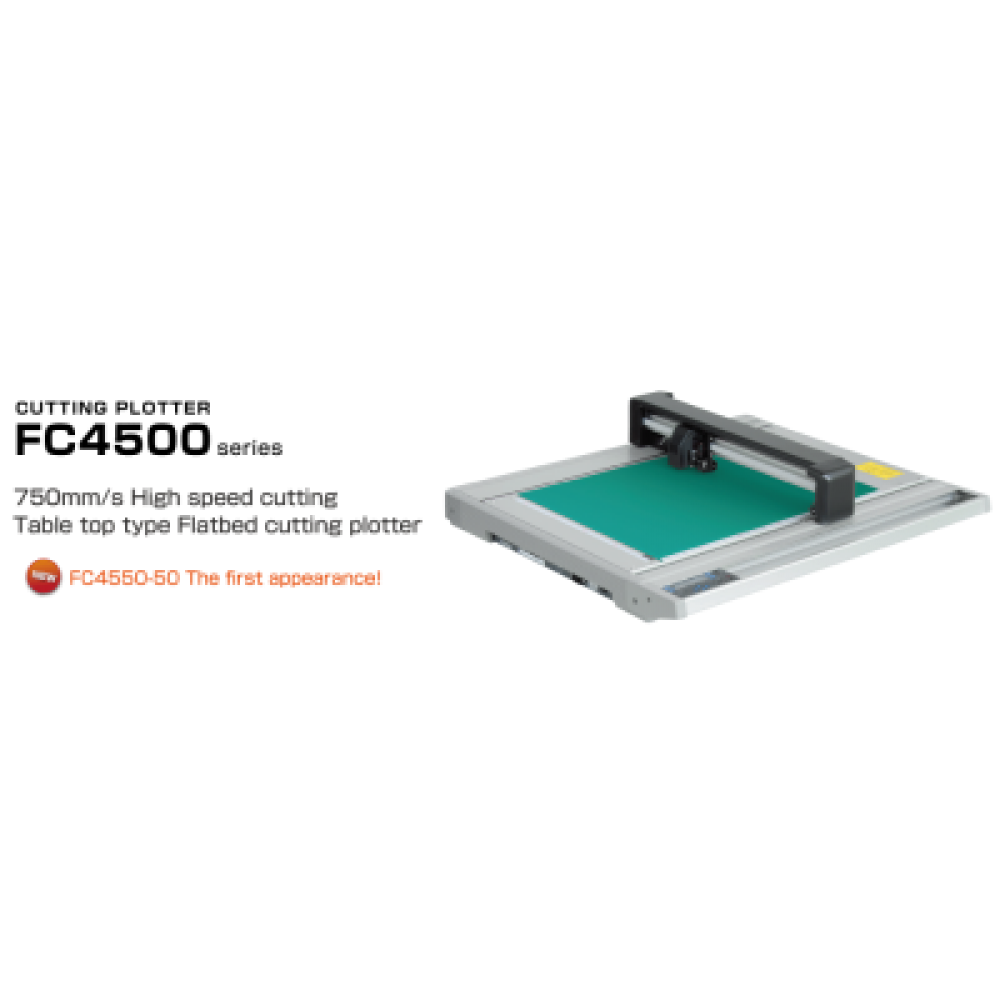

Graphtec FC4510-60

USD 4,925.00

Viewed 2530 times

Categories

Cart

Account

Search

Recent View

Shopping Cart

×

Your shopping cart is empty!

Search

×

Recent View Products

×

Product Description

Graphtec FC4510-60

Maximum cutting speed is 750mm/s Table top type cutting plotter with excelent cost performance

Flatbed cutting plotter is used for not only sign making but also for a wide range of industrial applicaitons and processes. Max.750mm/s cutting speed is useful for getting high productivity. The FC4500 Series are professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy. Compact size that can be set on a table with precise control of contour cut, half cut,perforated cut, and plotting.this FC4500 series is the most economical solution for cutting thick, hard materials that cannot be fed through a grit rolling type cutting plotter.

Model name FC4550-50 FC4510-60 Configuration Digital servo system, Flatbed Media hold-down method Cling mat Adhesive sheet / mat Effective cutting area 590 x 430 mm (23.2 x 16.9 inch) 860 x 600 mm (33.8 x 23.6 inch) Mountable media 500 mm (19.6 inch)

(Y-axis direction) 666 mm (26.2 inch)

(Y-axis direction) Media type Marking film (vinyl, fluorescent, and reflective)

Stiff paper/card (for stencils, etc.) up to 0.5 mm thick *1

Polystyrene foam sheets up to 0.8 mm thick *2

Sandblast rubber sheets up to 1.0 mm thick *2

Microflute board (F/G grades)

Clear sheets for plastic boxes

High-intensity reflective film *3 Maximum cutting speed 750 mm/s (30 inch/s) (1 to 75 cm/s in 23 steps) Cutting pressure Tool 1: Max. 5.88 N

(600 gf), in 48 steps

Tool 2: Max. 2.94 N

(300 gf), in 30 steps Tool 1, Tool 2: Max. 5.88 N

(600 gf), in 48 steps Minimum character size approx. 5 mm square (varies with the character font and media) Mechanical resolution 0.005 mm (5μm) Programmable resolution GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ *4 : 0.025 mm Distance accuracy Max 0.2% of the distance moved or 0.1 mm, whichever is larger *5 Perpendicularity Max 0.3 mm / 430 mm Max 0.4 mm / 610 mm Repeatability Max 0.1 mm *5 Standard interfaces RS-232C, USB2.0 (High speed) Buffer memory 2 Mbyte Command sets GP-GL and HP-GL™ *4 emulation (selected by menu) Number of tools 2 tools Cutter blade, pen,

and tool types Cutter blade: supersteel

Pen: oil-based ballpoint pen

Creasing/scoring tool Others ARMS (Advanced Registration Mark Sensing System), Reverse-side cutting and creasing with ARMS, Copy function, Creasing function, Repeatedly cut function Power supply 100 to 240 VAC, 50/60 Hz (Auto switching) Power consumption Max. 120 VA Operating environment Temperature: +10 to +35 degree C (44 to 95 degree F) , Humidity: 35 to 75% RH (non-condensing) Guaranteed accuracy environment Temperature: +16 to +32 degree C (55 to 90 degree F), Humidity: 35% to 70% RH (non-condensing) External dimensions

(W x D x H) *6 857 x 780 x 200 mm *7

(33.7 x 30.7 x 7.9 inch) 1172 x 962 x 200 mm *7

(46.1 x 37.9 x 7.9 inch) Weight approx. 19 kg (42 lbs.) approx. 27 kg *10 (60 lbs.) Compatible OS *8 Windows 10 / 8.1 / 8 / 7 / Vista, Mac OS 10.6 to 10.10 Certifications UL , cUL , CE making, FCC-A, EN55022-A, RoHS

Flatbed cutting plotter is used for not only sign making but also for a wide range of industrial applicaitons and processes. Max.750mm/s cutting speed is useful for getting high productivity. The FC4500 Series are professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy. Compact size that can be set on a table with precise control of contour cut, half cut,perforated cut, and plotting.this FC4500 series is the most economical solution for cutting thick, hard materials that cannot be fed through a grit rolling type cutting plotter.

| Model name | FC4550-50 | FC4510-60 |

|---|---|---|

| Configuration | Digital servo system, Flatbed | |

| Media hold-down method | Cling mat | Adhesive sheet / mat |

| Effective cutting area | 590 x 430 mm (23.2 x 16.9 inch) | 860 x 600 mm (33.8 x 23.6 inch) |

| Mountable media | 500 mm (19.6 inch) (Y-axis direction) | 666 mm (26.2 inch) (Y-axis direction) |

| Media type | Marking film (vinyl, fluorescent, and reflective) Stiff paper/card (for stencils, etc.) up to 0.5 mm thick *1 Polystyrene foam sheets up to 0.8 mm thick *2 Sandblast rubber sheets up to 1.0 mm thick *2 Microflute board (F/G grades) Clear sheets for plastic boxes High-intensity reflective film *3 | |

| Maximum cutting speed | 750 mm/s (30 inch/s) (1 to 75 cm/s in 23 steps) | |

| Cutting pressure | Tool 1: Max. 5.88 N (600 gf), in 48 steps Tool 2: Max. 2.94 N (300 gf), in 30 steps | Tool 1, Tool 2: Max. 5.88 N (600 gf), in 48 steps |

| Minimum character size | approx. 5 mm square (varies with the character font and media) | |

| Mechanical resolution | 0.005 mm (5μm) | |

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ *4 : 0.025 mm | |

| Distance accuracy | Max 0.2% of the distance moved or 0.1 mm, whichever is larger *5 | |

| Perpendicularity | Max 0.3 mm / 430 mm | Max 0.4 mm / 610 mm |

| Repeatability | Max 0.1 mm *5 | |

| Standard interfaces | RS-232C, USB2.0 (High speed) | |

| Buffer memory | 2 Mbyte | |

| Command sets | GP-GL and HP-GL™ *4 emulation (selected by menu) | |

| Number of tools | 2 tools | |

| Cutter blade, pen, and tool types | Cutter blade: supersteel Pen: oil-based ballpoint pen Creasing/scoring tool | |

| Others | ARMS (Advanced Registration Mark Sensing System), Reverse-side cutting and creasing with ARMS, Copy function, Creasing function, Repeatedly cut function | |

| Power supply | 100 to 240 VAC, 50/60 Hz (Auto switching) | |

| Power consumption | Max. 120 VA | |

| Operating environment | Temperature: +10 to +35 degree C (44 to 95 degree F) , Humidity: 35 to 75% RH (non-condensing) | |

| Guaranteed accuracy environment | Temperature: +16 to +32 degree C (55 to 90 degree F), Humidity: 35% to 70% RH (non-condensing) | |

| External dimensions (W x D x H) *6 | 857 x 780 x 200 mm *7 (33.7 x 30.7 x 7.9 inch) | 1172 x 962 x 200 mm *7 (46.1 x 37.9 x 7.9 inch) |

| Weight | approx. 19 kg (42 lbs.) | approx. 27 kg *10 (60 lbs.) |

| Compatible OS *8 | Windows 10 / 8.1 / 8 / 7 / Vista, Mac OS 10.6 to 10.10 | |

| Certifications | UL , cUL , CE making, FCC-A, EN55022-A, RoHS | |